When it comes to quality control, sometimes the smallest details can reveal the biggest problems.

Case in point: Van Halen’s legendary “Brown M&M’s” test.

Van Halen was one of the most iconic rock bands of the late 20th century, known for their electrifying performances, technical prowess, and a string of massive hits. But why do we talk about them here?

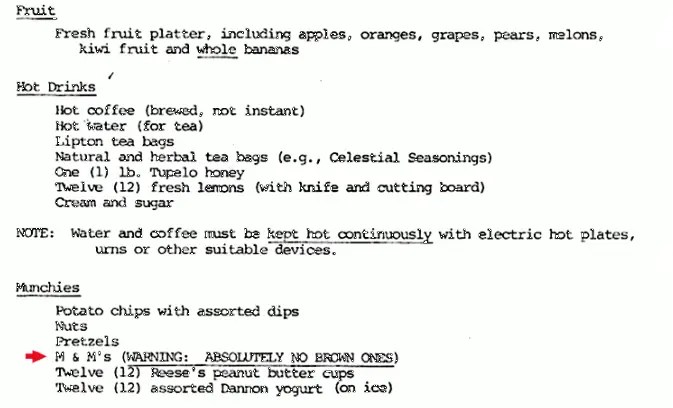

In their concert contracts, Van Halen included a seemingly absurd demand: a bowl of M&M’s in the backstage area—with all the brown ones removed. At first glance, this seemed like rock star excess, the kind of ridiculous request made by prima donnas. But in reality, it was a brilliant quality control mechanism.

Van Halen’s stage shows were massive undertakings, involving tons of equipment, complex lighting rigs, and pyrotechnics. A single oversight could result in serious safety hazards, from stage collapses to explosions. The contract spelled out every detail required to keep the band, crew, and audience safe. But how could they be sure promoters actually read and followed the instructions? Simple: the brown M&M’s test. If they walked backstage and saw brown M&M’s in the bowl, they knew the contract hadn’t been thoroughly reviewed—and if something that small was overlooked, what else had been missed? Time for a full safety check.

This concept isn’t just useful in rock and roll. It’s the same principle behind debugging and defect seeding in software development—intentionally planting small errors to test quality control systems. It’s also used in industries like retail (mystery shoppers), security (undercover inspections), and cybersecurity (red teaming). These covert tests work because they directly measure what matters: attention to detail and adherence to protocol.

The beauty of this approach? It’s low cost, low risk, and easy to implement across industries.

Instead of avoiding brown M&M’s, consider planting them near safety-critical or mission-critical processes. Keep their exact form and placement a secret, but make people aware they exist—this promotes vigilance while reinforcing trust. After all, true quality isn’t about catching mistakes after the fact. It’s about designing systems that prevent them in the first place.

Leave a comment